Rakanpur, Ahmedabad, Gujarat

- GST NO. : 24AJPPM2507C1ZJ

Plastic Injection Molding Services

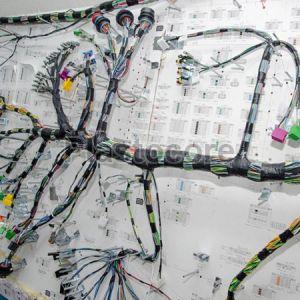

Plastic injection moulding services

Plastic injection moulding services engage in the manufacturing procedure of producing plastic parts and components by injecting molten plastic stuff into a mould cavity. The process of designing starts with the design of the part to be created. The design engineer’s 3D CAD models of the part, which are used to make prototypes, use techniques such as CNC machining and 3D printing. Prototyping allows for testing and validation of the design before mass manufacture.

Plastocore is an outstanding provider of advanced plastic injection moulding services. We provide a complete manufacturing solution that covers every feature of raw matter verification, tool making, finishing, part fabrication, and final inspection. Our team of manufacturing experts is dedicated to giving you the best level of professional assistance for plastic injection moulding services of any complexity or size.

Plastocore gives several benefits to plastic injection molding. They have the special ability to make large volumes of parts quickly, high surface quality, several resins to select from, colour flexibility, and strong tooling that can last for years.

If you are interested in the best quality of plastic injection moulding services, you can contact our team to find out more information.

Looking for "Plastic Injection Molding Services" ?

Explore More Services